Conscious materials

At mtng we care about the present, but always keeping an eye on the future. For this reason, our collections and processes incorporate, season after season, new advances with the aim of making each of the products we manufacture more sustainable and environmentally friendly.

Because at mtng we believe that the world we live in is not an inheritance from our parents, is a loan from our children.

Vegan Collection

Part of our collection of sportswear for girls (Gravity) has the INESCOP certificate that guarantees that the chemical nature of all its components does not correspond to animal fibers (namely fur with hair, leather, silk, wool or down).

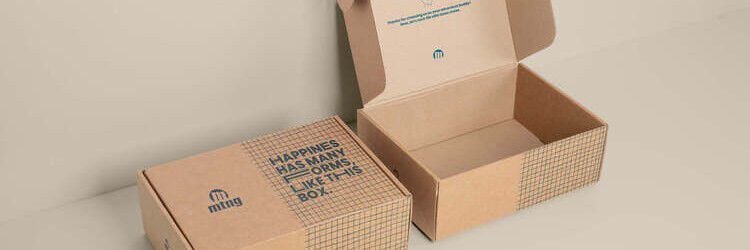

Recycled Packaging

When it comes to sustainability, at mtng we believe that the content is as important as the container. That is why most of the elements of our product packaging are made from recycled materials and are fully recyclable, so that you are the one who closes the circle.

That is why every time you receive an order from mtng you are taking care of the environment.

Mtng packaging is made of recycled material under FSC (Forest Stewardship Council) certification, a global organization dedicated to promoting responsible and sustainable forest management.

Our box pair (MTNG and MM) are printed with the label "FSC MIXED" with the license number given to the packaging supplier. The products bearing this label are made with a mix of materials from FSC certified forests, recycled materials... all of them controlled by FSC.

The individual bag that each shoe or purse comes in is an anti-mold MPX2 Polybag made of 100% recycled LDPE (Low Density PolyEthylene) Micro-Pak, which can be recycled after using it. The hemp twine is fully recyclable.

Leather Working Group

Leather Working Group (LWG) is a global multi-stakeholder community committed to build a sustainable future with responsible leather. It is a non-profit organization driving best practices and positive social and environmental change for responsible leather production.

Leather Working Group is an international non-profit organization responsible for the world's largest leather sustainability program.

LWG aims to improve the environmental impact of the leather industry by assessing and certifying leather manufacturers.

This standard is used to evaluate leather manufacturers on the following aspects:

- Water and energy use.

- Solid waste and effluent management.

- Air and noise emissions.

- Traceability.

- Health and safety.

- Chemicals management.

- Restricted substances, compliance and management of chromium VI (CrVI).

Water based PU

PU leather is a synthetic leather made with water based polyurethane. It is the ultimate replacement product for traditional solvent-based synthetic leather. In addition, it does not contain certain toxic organic solvents. Compared with the traditional synthetic leather process, it greatly reduces energy consumption and waste, and actually achieves low-carbon production and energy conservation and environmental protection. It is free of DMFa and VOC's (Volatile Organic Compounds) and is harmless to human.

Water based PU leather (also known as solvent-free PU leather or DMF-free PU leather) is developed using leading international technology concepts and process equipment. This material uses water-based polyurethane resin and contains no solvents, can achieve a DMF content of 0, and complies with regulations such as REACH, RoHS and Oeko-Tex 100, among others. Compared to the traditional synthetic leather manufacturing process, it significantly reduces energy consumption and waste generation, achieving a low-carbon and environmentally friendly production.

Advantages of DMF-free PU leather compared to other traditional synthetic leathers:

- Water based PU is soft and smooth.

- It does not contain DMF.

- The manufacturing process of Water based PU is environmentally friendly as it eliminates the use of solvents and chemicals, and does not contain harmful substances such as heavy metals harmful to human health.

.jpg?sw=750)

Recycled materials

At the beginning of each campaign we work in detail all the materials to be used in each collection. Always looking to improve the supply chain and our manufacturing processes, in each season we incorporate more recycled materials.

Part of our collection is made with recycled materials in the cutting part. The use of these materials reduces the consumption of the raw material itself.

Within our collections we have certain products in which we use a percentage of recycled materials. Among these products are the Persea and Tanubis boots, where the main cut composition is 30% post-consumer recycled polyester and 70% polyester. In addition, products such as the Aria, Bequia or Denver, whose main material is canvas, contain 60% pre-consumer cotton and 40% conventional cotton.